The mandrel is steel, and the hat is steel. This particular rivet is steel and steel. So, let's review the different materials available and types of rivets. I'm Bob and today we're going to talk about the different types of rivets available and the materials they come in. POP Rivet Types and Materials | Fasteners 101īob: Welcome back to Albany County Fasteners - Fasteners 101. Pop Rivets included in Rivet Kits are either corrosion resistant Stainless Steel, or lightweight Aluminum as described in each kit title. These fastener assortment kits include popular size runs of pop rivets in domed head, countersunk, closed end and large flange varieties in both 304 stainless steel and aluminum. Pop Rivet Assortment Kits Assorted Size Runs of Blind Rivets Domed head rivets in this selection are commonly referred to as both Interlock and Structural Rivets. Structural or interlock blind rivets create a more robust assembly than standard pop rivets because of the amount of force they generate. Tri-Fold Rivets are commonly used in automotive, trailer, and appliance applications. This makes a wider bearing load spread, which is ideal for thin metals and plastics. Tri-Fold Rivets are designed to create three anchor points on the blind side of the installation. One Multi-Grip Rivet can be used as an equivalent for at least three different rivet sizes. One size of Multi Grip rivet can be suitable for a variety of jobs, including mismatched holes. This grip range allows for flexibility in design and a lower rivet inventory. One Multi-Grip Rivet has a grip range of different sizes. Multi-Grip Rivets can substitute in applications where the thickness of the riveted material varies. Large Flange Rivets are tubular, comprised of a hat and mandrel the mandrel's length is snapped off when installed. Large flange, also known as Oversized, have a larger washer on the hat than standard. The hat of the rivet is almost inverted, with a 120-degree countersink in the integrated washer. They are used in tracks where the head will not protrude into sliding tracks or rollers. Countersunk RivetsĪ countersunk blind rivet, also known as a Flat Rivet, is used in countersunk holes and, once set, finish flush to the surface. The mandrel is encased within the blind rivet itself. Also known as a waterproof rivet, they are distinguished by their flat top.

Closed End RivetsĬlosed-End Blind Rivets differ from a standard pop rivet in that they feature a flat, closed end, which creates a watertight seal. Color options are available in aluminum for this type. Open-end rivets are available in stainless steel, aluminum, and zinc-plated steel. Open End Rivets get their name because the mandrel is exposed at the rivet's bottom before installation. Open-end blind rivets create a fast and tight assembly however, they are not watertight. The answer is MANY! See the list of available options and descriptions below: Open End Rivets How many varieties of Blind Rivets are available? Once gripped, the mandrel snaps, holding the rivet in place. A pop rivet gun is set on the rivet, pulling the mandrel into the rivet body, making it grow and grasp the pieces together. The rivet body is then brought into contact with the parts. A pop rivet is then embedded through the hole. Where access to the two sides of a segment is constrained, a hole is first made through the parts to be joined. The initial segment is known as the rivet body (also called shell or cap), and the second part is known as the mandrel (also called the stem). Trade Names: Blind, Domed Open End, Closed End, Countersunk, Large Flange Open End, Multi Grip and Structural Rivets How do Pop Rivets work?

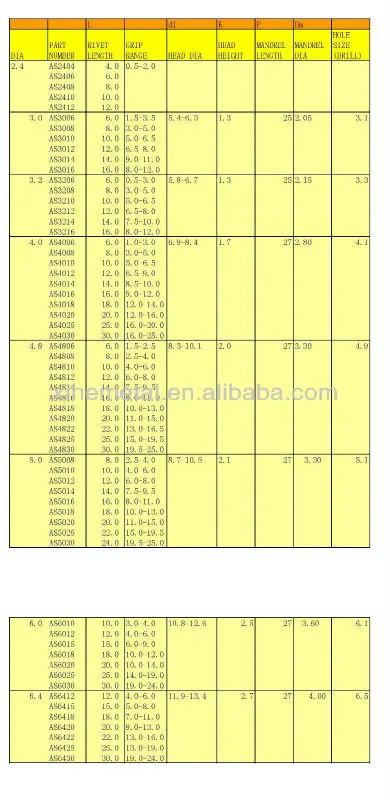

Rivets are measured in installed grip range and length. The hat and mandrel can be made from the same material or a combination of two materials. They are tubular and comprised of a hat and mandrel the mandrel's length snaps off when installed. POP rivets connect two pieces of material in a quick, efficient manner with a hand riveter or pneumatic rivet gun.

0 kommentar(er)

0 kommentar(er)